Plant List

Engineering Plant

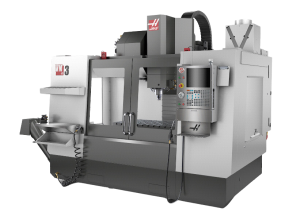

Milling

Haas VM3 5 axis CNC machining centre 1000 x 600 CAD_CAM link

Haas VM3 5 axis CNC machining centre 1000 x 600 CAD_CAM linkHaas VM2 4 axis CNC machining centre 760 x 500 CAD_CAM link

Haas Super MiniMill2 CNC machining centre CAD_CAM link

Haas Super MiniMill CNC machining centre CAD_CAM link

Haas Super MiniMill CNC machining centre CAD_CAM link

XYZ 2000 Turret Mill with DRO XYZ

XYZ 3000 Turret Mill with DRO XYZ

KVR 3000 5 HP Turret Mill fitted with Acu-Rite DRO

Turning

Haas TR1 CNC Turning centre

Haas TR1 CNC Turning centreTryax Cnc Turning Centre

Colchester Triumph 2000 190mm Centre height x 1270mm Bed complete with Hepworth Hydraulic Copy Turning Unit

Colchester Triumph 2000 Short Bed Gap Lathe with Hepworth Hydraulic Copy Turning.

EDM Wire / Spark Erosion

Fine Sodick A325 Super precision 4 axis Fully submerged, Auto wire feed, CNC Wire erosion machine, max. travel X 400mm,Y 300mm ,Z 250mm

Fine Sodick A325 Super precision 4 axis Fully submerged, Auto wire feed, CNC Wire erosion machine, max. travel X 400mm,Y 300mm ,Z 250mmFine Sodick SLC400G 4 axis Fully submerged, Auto wire feed, CNC Wire erosion machine, Linear motor Drive on X,Y,U,V axis, Touch screen, High speed threading

Fine Sodick AM35 4 Axis Full CNC Spark Eroder capable of superfine finishes of 1uR max.,

4 Station tool changer , threads, helix’s, reverse tapers, etc.

Fine Sodick AD35L 4 Axis Full CNC Spark Eroder ,4 Station tool changer capable of superfine finishes of 1uR max.

threads, helix’s, reverse tapers, etc.

Fine Sodick K1C Small hole EDM drilling machine 0.3mm to 3mm Dia.

Grinding

Euro Spark CNC Surface Grinder,

Euro Spark CNC Surface Grinder,Jones & Shipman 540 Surface Grinder complete with Opti Dress Wheel Forming Equipment

Jones & Shipman 540P fitted with Diaform 10-1 Wheel Forming Equipment

Jones & Shipman Cylindrical Universal Toolroom Grinder 254 x 609 Exterior 203 x 254 Interior Equipped with Wheel Forming Facilities.

Miscellaneous

Shot – Blasting Equipment

Shot – Blasting EquipmentWork holding between machines using the latest equipment from System 3R

Electrox Laser Engraving system with Rotary axis

Injection Moulding Plant

Moulding, Welding, Assembly & Testing

Arburg 570C ( 200 Ton ) Golden Edition with Selogica

Direct Touch Screen control system.

Arburg 570C (200 Ton) Golden Edition with Selogica

Direct Touch Screen control system.

Arburg 570C (200 Ton) Golden Edition with Selogica

Direct Touch Screen control system.

Arburg 570C (200 Ton) Golden Edition with Selogica

Direct Touch Screen control system.

Arburg 320 C 500 – 170 ( 50 Ton ) Golden Edition with Selogica

Direct Touch Screen control system. Sited in White room.

Arburg 320 C 500 – 170 ( 50 Ton ) Golden Edition with Selogica

Direct Touch Screen control system. Sited in White room.

Arburg 320 C500 – 170 ( 50 Ton ) Golden Edition with Selogica

Direct Touch Screen control system.

Arburg 320 C 500 – 170 ( 50 Ton ) Golden Edition with Selogica

Direct Touch Screen control system.

Arburg 320 C500 – 170 ( 50 Ton ) Golden Edition with Selogica

Direct Touch Screen control system.

Arburg 320 C 500 – 170 ( 50 Ton ) Golden Edition with Selogica

Direct Touch Screen control system.

Arburg 270U Allrounder sited in White room.

Other

Robotic part pickers, Hopper drier’s,Hopper loaders, Conveyors and mould heaters.Rinco Ultrasonic plastic welding machines at 20 KHz ,35 KHz. and 70 KHz

Electrox Laser marking System,

Hot Foil Printing Equipment,

Vacuum, Pressure testing equipment,

General product testing to suit specification.

Sub contract Ultrasonic Plastic welding available